SATEL Toolroom

Top quality, on time delivery and after sales service are the main attributes of SATEL Toolroom.

These values have been appreciated since the beginning of SATEL Toolroom operation in 2002 by our customers – manufacturers representing leading branches of industry, such as automotive or electrical engineering.

SATEL Toolroom specialises in manufacturing injection moulds for thermoplastics. We provide comprehensive services: from the design of a moulded part, through mould making, to testing on injection moulding machines. On request, it is also possible to start the production of mould inserts in our Injection Moulding Department.

These values have been appreciated since the beginning of SATEL Toolroom operation in 2002 by our customers – manufacturers representing leading branches of industry, such as automotive or electrical engineering.

SATEL Toolroom specialises in manufacturing injection moulds for thermoplastics. We provide comprehensive services: from the design of a moulded part, through mould making, to testing on injection moulding machines. On request, it is also possible to start the production of mould inserts in our Injection Moulding Department.

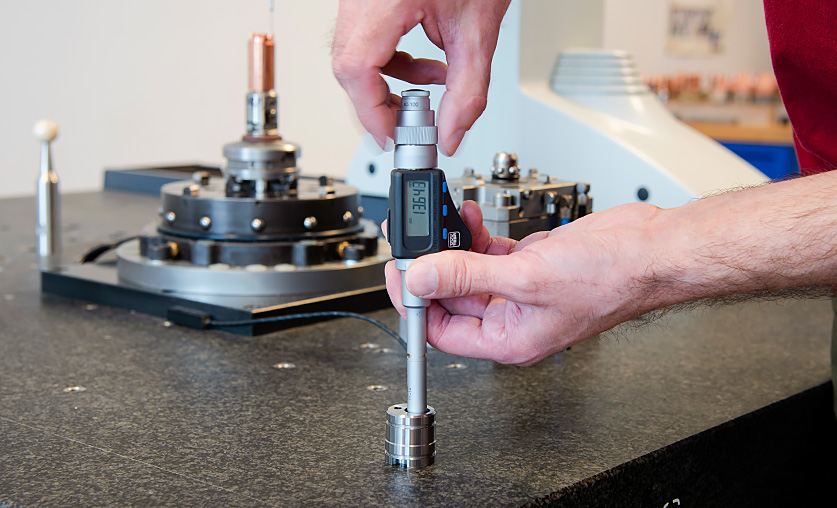

ACCURACY AND PRECISION

Proper conditions in air-conditioned rooms, the use of modern CNC machine tools and advanced control technology are factors that ensure high precision of our tools and equipment. Our staff consists only of qualified specialists with many years of experience. Their knowledge and skills, supported by modern, specialised equipment, are our prerequisites for the completion of even the most complex orders.

Air-conditioned production rooms, service supervision over the machine tools and a well-equipped measuring room with a modern coordinate measuring machine are factors which contribute to the high quality of all the products manufactured at SATEL. Multiple inter-operational checks carried out during production and quality management procedures minimise the possibility of shortcomings.

We continue to improve the quality of our services and products through regular staff training, implementation of the newest available high-end technologies and tools.

Air-conditioned production rooms, service supervision over the machine tools and a well-equipped measuring room with a modern coordinate measuring machine are factors which contribute to the high quality of all the products manufactured at SATEL. Multiple inter-operational checks carried out during production and quality management procedures minimise the possibility of shortcomings.

We continue to improve the quality of our services and products through regular staff training, implementation of the newest available high-end technologies and tools.

TOP

QUALITY

Top quality, on time delivery and after sales service are the main attributes of our services. Since the very start of the Toolroom operation in 2002, up to this day, they have been appreciated by our customers - different manufacturers representing leading branches of industry, such as automotive or electrical engineering.

Tomasz Grzelak

TOOLROOM AND INJECTION MOULDING DEPARTMENT MANAGER

Smart VLOG

Smart VLOG